I am starting to explore the most powerful tool in a distiller’s arsenal, the birectifer, which is now for sale [$900 USD]

Arroyo described it as invaluable for the yeast research he conducted, but what did that look like and how may that help brewers, cider makers, and distillers today?

The only protocol Arroyo spells out in Studies on Rum is the distilling of 250 ml of 40% ABV distillate, but that isn’t likely the only protocol he used. 250 ml * .40 means that there is 100 ml of absolute alcohol in the distilling flask. This means we can bypass another still as intermediary and directly put in enough ferment to contain 100 ml of absolute alcohol.

10,000 / (alcohol % of ferment) = ml of ferment that needs distilled.

If the wash has 8% ABV, then 1250 ml of wash are needed.

If the wash has 7% ABV, then 1429 ml are needed.

If 6% ABV then 16667 ml, etc.

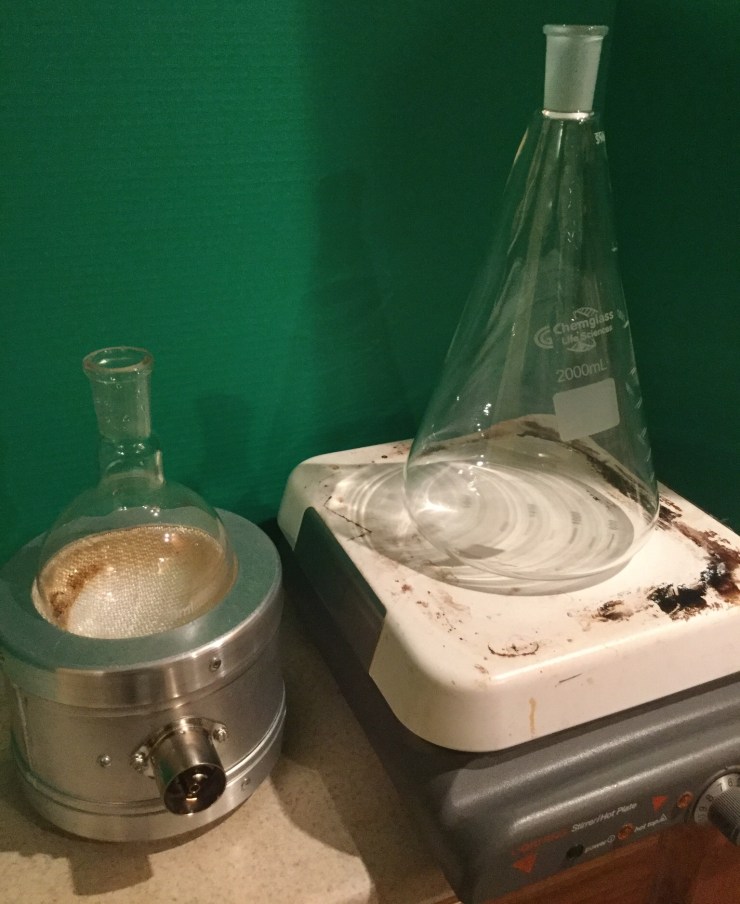

This would simply require a 2000 or 3000 ml boiling flask. Very economical is a Erlenmyer with 24/40 taper on a hot plate controlled by a Variac.

Typically, when yeasts are compared, they will be using the same model ferment and it is already known that they can ferment it to dryness. Congeners will line up in the fractions and be comparable using all the classic German organoleptic tests we’ve already been exploring.

Beer brewers and cider makers may want the first fraction to be full of ethyl-acetate because it can enhance fruitiness. Distillers may want the lightest of their choices because when they distill, they already have a surplus and know they have to cut it away or let it fade during maturation. Rum distillers may follow the path of Arroyo and give most of their attention to fraction five which regulates quality. They may hope to strike rum oil! At the same time they are hoping that fraction four will be low in fusel oil. It is all about the ratios which the birectifier makes apparent.

Once you select your yeast, you need to optimize your ferment and watch out for off aromas. Arroyo covers much of this in Studies on Rum such as differing the amount of yeasts pitched, the pH and/or the titratable acidity. We have recently learned of the concept of Δ acidity from M. Miniac which has not been sufficiently explored in the context of full flavored products. Spectacular studies of off aromas have been conducted by the INRA in Martinique and I translated numerous of their papers from French. Research has been collected relating to near every scenario across many spirit types and the birectifier is the central tool to help apply it all.

Beer brewers may value the birectifier’s way of identifying off aromas in fractions 6,7, and 8 as they walk on the wild side with brett beers and chaotic sours. Rum distillers are right behind them!

In the category of batch by batch still tuning, which is especially important when a production is very new, we get some great ideas from Cognac. Robert Léauté, in his 1989 James F. Guymon Lecture: Distillation in Alambic [which I annotated five years ago], describes Cognac distillers sometimes performing small scale micro distillation pre big-rig alembic distillation.

Cognac distillers are perfectionists. They cannot expand capacity because they’ve cultivated every inch of their region, they can only improve quality so they do. They also ferment all their wines at once so batches enter a queue as they wait to be distilled. Much can happen while waiting in line, good and bad, that may need to be adjusted for.

Léauté mentions the use of micro distillation where glass lab-ware is used with copper shavings placed in the boiler to a give a glimpse of flaws that cannot be noticed by tasting the wine alone.

Quality controls on wines: Today, the distiller has three means to check the quality of wines for distillation in an alembic: tasting, analysis, and microdistillation. The microdistillation is conducted in a laboratory still with copper shavings placed in the boiler. This technique is very useful to detect the following by tasting: high acetaldehyde; too much ethyl acetate; acrolein; butyric smell; oxidization characters; high level of volatile phenolic compounds; and pollution by sulfury compounds, hydrocarbons, etc.

The birectifer is the tool to maximize the potential from quick organoleptic analysis after micro distilling. Its output is the easiest to decode and translate into action. Too much ethyl acetate means either cuts will need to be adjusted or distillation proof will need to be increased (pH buffer could also be tuned!). Acrolein comes from Corynebacteria bacteria and I’ve translated great literature on it. It is responsible for peppered whiskies which is considered a fault.

If you have a 200 gallon batch that may have run away, why not go into it with a better understanding of what you are going to encounter? Active time, inactive time on capital like the still, fuel to power it all, and the cost of barrels are so high that you should know.

It is known that by 1975 large scale rum distillers were able to pre-analyse distillates before running them through a continuous still. They adjusted variables based on the data, especially fusel oil separation by extractive distillation, to get a predicted output. Unique streams could be spliced in without ever interrupting the still and a custom output received before returning to regular bulk work.

When we eventually deploy our automation kit for the birectifer, which dramatically reduces active time collecting the fractions, it will be hard to justify not pre-analyzing ferments before distillation. Big-rigs can eventually be automated with the data further reducing active time and justifying the expense of full featured labs.

2 thoughts on “Yeast Exploration, Fermentation Optimization, and Still Tuning With the Birectifier”