Follow along: IG @birectifier

[This is a 50 page document and it is a lot… Next up is to quicly publish an abridged version that removes a lot of parts that may not fully interest lay readers or people short on time. That is going to be followed up by a post laying out all the known first person accounts of producing Jamaica rum.]

THE DISTILLATION OF RUM.

By R. H. BURTON.

In reading, as I regularly do, the interesting columns of The Sugar Cane, it has often occurred to me that a paper on the distillation of rum would be useful to many planters. The only article on the subject which I can at present bring to my recollection is one by Mr. Patrick Neilson, of Trelawney, Jamaica, which appeared in No. 21 of this magazine.

The superiority of Jamaica rum is one of those old-established facts that admits no gainsaying. But the question is—why should it be so ? Is it owing to some peculiarity of the soil ? Or to the superior mode of manipulation?

For instance, in Demerara, where I understand much attention is paid to distillation, they use no dunder in setting up their wash, alleging, as a reason, that it makes inferior rum. Yet Demerara rum never meets with as good a market as that of Jamaica, where, on many estates, they use no water. Which of the two sets of planters are right? One would be inclined to side with the most successful. For myself, though a practical planter, I must confess I learnt distillation by the old rule of thumb, as most youngsters in the Windward Islands in those days did, when Sykes’ hydrometers and Baumé’s saccharometers were unknown in West Indian still and boiling houses. I used to make tolerably good rum; but, like many others, it never occurred to me to know or inquire whether it paid or not. Skimmings were taken off the coppers; it was a pity to throw them away when a stillhouse was on the property, consequently the molasses thought requisite was spared, and, to take advantage of the skimmings, some rum was made. I believe, if you were to inquire of planters, not Jamaicans, this would be the reason generally alleged for making rum at all.

Afterwards, during two crops, I paid some attention to distillation. We had a reasonably good still and liquor loft; our molasses were not of the first quality, though, strange to say, our sugar was, and was sold well in the neighborhood for home consumption. Then, as subsequently, I have always made a small quantity of really good rum for acquaintances; therefore, without any pretensions to be a distiller, I fancy I know just as much about it as most planters, or at all events how to appreciate the superior merits, if not of the “Old Jamaica,” at least of the Jamaica distiller. In journeying about Jamaica I have visited many estates, made minute inquiries of the various distillers respecting their process, have found them always very willing to communicate; and though I have found a great diversity of opinion on small matters, yet, on the whole, one system is in general use. On one estate which I visited, and where the rum was remarkably good, the distiller told me he used vinegar to mix with his baked or burnt sugar for colouring; another assured me the only good colouring could be made by the addition of strong rum; a third preferred to cool down with water, and a fourth advocated purified dunder; yet each in his way made very good colouring. So I was led to imagine they were all right, and the main points were care, attention, and cleanliness; indeed, I have not seen an untidy distillery in Jamaica; they are a credit to the men in charge.

I have looked carefully through many distilleries, talked over the question of distillation with many planters during a twelve months’ residence in Jamaica ; but in one of my jaunts through the country I had the pleasure of spending a few days with Mr. T. Ellis (manager and attorney, Morelands Estate, in Vere, the property of Mr. Mitchell), from whom I gained much information on the subject of Jamaica distillation. His vat room is one of the best I have seen, and he kindly lent me two old papers, from which I copied the following two very interesting letters, written by the late Professor Hoffmann. Mr. Kennedy, to whom I ventured to apply, informed me that he had not published his treatise, and that the manuscript had been lost; but he was so courteous as to reply to my queries; and finally I picked up a “Treatise on the distillation of Rum, by a practical distiller.” The latter does not contain much practical information, and it might be regretted its author had not confined himself to the practical, as Professor Hoffmann did to the scientific portion of the operation. There is one peculiar feature about Jamaica rum; the same distiller does not generally produce equally good rum on two different estates. Whether this depends on the still and apparatus for fermenting the liquor, or the quality of the soil on which the canes, from which the ingredients are extracted, are grown, is a question I have frequently heard debated. Possibly the formation of the fermenting or vat room has much to do with it.

[What I love is that we are seeing the development of a terroir mythology.]

IMPROVEMENT IN THE DISTILLATION OF RUM.

BY PROFESSOR HOFFMANN (late Island Chemist).

[Copied from “The Jamaica Advertiser and Henderson’s Daily News Rocord,”

May 1st, 1860.]

(Advertiser.)

“Yesterday’s post brought me some good news from an esteemed friend at Dry River, Vere.”

“They are doing great things there. He says—’We have been trying alum in the still house here, and find that it has a magical effect.’ This alum is no doubt the great arcanum of Mr. Ellis, of Demerara. It is curious to observe how slowly some improvements in sugar boiling and in distillation find their way to the Colonies.” [Alumn can be used as a flocculent to clarify liquids.]

“It requires some enterprising individual to put a high price upon his pretended secret, in order to draw attention to it. Ten years ago I gave the reason why dunder increases the yield in rum, and lately I have been penning some observations on the distillation of rum, which embody all that can and ever will be done to increase the field of rum, from a given amount of sweets, to its utmost extent.”

“It was originally my intention to write several articles on the distillation of rum; but having since been informed that Mr. Kennedy, of St. Thomas-in-the-East, is about publishing a treatise on the same subject, I shall restrict myself entirely to those features of the process which are of purely chemical importance. To-day, Alum shall be the subject of discussion.”

“There is only one way in which alum can act upon wash, and that is by the sulphuric acid or oil of vitriol which it contains. Now alum is an article little if ever inquired for in the market, while oil of vitriol is abundant. I believe, therefore, that it may be of some service to my enterprising friends in Vere to know that one pound of sulphuric acid, or oil of vitriol, is equal in effect to a little more than three pounds of alum. There is, however, some precaution to be taken. Sulphuric acid, when employed in excess, may injure the stills (so may alum), and accumulate in the dunder to such an extent as to check fermentation instead of aiding it. Now, whenever the copper of the still, after distillation, appears to be particularly bright below the level of the surface of the dunder, it is high time either to throw away the dunder, or to add some wood ashes, or temper lime to it, so as to take away the greater part of the acid.”

“I see no reason why the dunder should not be thrown away now and again. A very good fermentation will take place with skimmings, molasses and water, besides the alum, or sulphuric acid, without the dunder. Another annoyance which will show itself, in consequence of the employment of alum or sulphuric acid, is the formation of a crust in the still; this must be removed as often as practicable, for if this crust of sulphate of aluminate of lime is allowed to acquire any considerable thickness, it cannot be removed without the greatest danger to the still. Putting some coarse sea sand into the still at every distillation may obviate this danger in some measure.”

“The action of alum or sulphuric acid can be readily explained. When cane juice is defecated by lime, a part of the lime goes into combination with the aluminous matter, organic acids, etc., another and a greater part combines with sugar and forms what is called saccharate of lime. One pound of lime combines with six pounds of sugar. This saccharate of lime is found in the molasses. It is an antiseptic substance, and prevents or checks fermentation, so much so that cane juice, when mixed with a sufficient quantity of lime, may be preserved for many years perfectly sound.

“By adding sulphuric acid to the molasses and skimmings, the saccharate of lime is completely decomposed, gypsum is formed, and the sugar is liberated. Dunder acts in precisely the same manner, as it contains large quantities of acetic acid.”

“However, the acid in the dunder is rarely sufficient to decompose the whole of the lime salt, especially on estates where large quantities of temper lime are used for defecation. The planters of Demerara will, consequently, derive more benefit from the employment of sulphuric acid than those of Jamaica.” [This is saying that Jamaica used more lime in their sugar refining than other islands.]

(Daily News Record, May 3rd, 1860.)

“I will continue to-day observations on the theory of the distillation of rum.”

“Besides decomposing the saccharate of lime existing in the wash, the acetic acid in the dunder performs another function during distillation, namely,—the acetic acid of the dunder, supposing it to be in excess in the wash, will form a small quantity of acetic ether, which decidedly improves the flavour of the product. Ten years ago, when I started this hypothesis, no experiment had been performed in order to prove or disprove this point. My esteemed friend, Mr. James Mitchell, at St. Jago estate, was the first who attempted to verify its correctness, and expressed satisfaction at the result. The following are his words :—’I have been also trying an experiment in distilling high wines, with about 1% of sulphuric acid and 2% of acetic acid. I think the result good. When I try it again I would use about 2% of acid and 3% of acetic acid.'”

“Then, again, dunder contains a large quantity of ferment or yeast, rendered inert by the heat to which it was exposed in the still. By exposing such inert albuminous matters to the action of the oxygen of the air they undergo a change, which restores to them in a great degree the power of producing fermentation. Hence the advantage of exposing dunder to the atmosphere in shallow vessels. If two dunder cisterns were used, so much the better, as they might be employed alternately, and thus allow each portion of dunder to be exposed for a longer period to the action of the atmosphere to manifest advantage.”

“In connection with this may be mentioned a great advantage resulting from the employment of acids, when these acids are mixed with the skimmings. Everyone is aware that during defecation the albuminous matters in cane juice are coagulated and rendered inert. Now, it is exactly these albuminous matters which produce the yeast necessary for the fermentation of sugar. The more yeast we have in our wash, the better will be the fermentation, the more rapidly it will run its course, and, consequently, the larger will be the yield of rum.”

[This paragraph may be an important early bridge from plain skimmings to sugar cane vinegar.]

“There is another advantage to be gained at the same time, namely, this—that the wash may be set higher than usual and more rum may be gained at the same expense for labour and wood; because the more yeast material there is in the wash, the more sugar will be decomposed into alcohol and carbonic acid. It is well known that heavy wash will give heavy dunder, and a small return for the amount of the sweets employed. Now, we have it in our power to gain a considerable quantity of yeast material in addition to what we can dispose of at present in molasses, clarified skimmings, and clarified dunder. We have only to add a slight excess of acid to the skimmings in the skimming cistern, and stir it well up. After this, allow it to clarify, and draw off the clear liquor. Most of the inert albuminous matter will be brought into solution, and contribute towards a favourable and rapid fermentation.”

“After these explanations the drift of my observations contained in a Report to His Excellency the Governor will be all the better understood. The following are the words used :—”Proprietors in England hare frequently expressed their surprise why the wash for distillation cannot be set as high in the Colonies as in England. I have answered this question by drawing their attention to the fact that distillers in England use yeast for producing powerful fermentation, while the Colonial distiller does not. Then, again, the English distiller works mostly upon starch—sugar obtained from grain or potatoes, mixed with treacle,—while the Colonial distiller works upon cane sugar, which has first to be transformed into grape sugar (starch sugar) before it can undergo fermentation. This change from cane sugar to grape sugar has to be produced by the sacrifice of part of the yeast material existing in skimmings, dunder, and molasses, (the ingredients of wash). Now for the conversion of a given amount of grape sugar into alcohol and carbonic acid, it requires a definite amount of yeast material. If there be more sugar than yeast (proportionately) in the wash, a part of the sugar remains undecomposed, and goes into the dunder, which thereby becomes heavy. A great loss is sustained in this manner. If we possessed the means of converting cane sugar into grape sugar, without employing yeast, we would have all the effect of the yeast reserved for the production of alcohol (rum).”

[What we see here may be the development of the obsession inverting the sugar via acids that we see in later writings.]

“’But this is not all. We can get the wash higher than usual at the same time. By the addition of artificial yeast we might set it still higher, yet chemistry offers no means for the conversion of cane sugar into grape sugar. Prolonged heating of the molasses alone will effect it; but the boiling of the molasses with some sulphuric acid will be far the more efficacious.'”

“The production of artificial yeast is a problem already solved by chemistry, and, therefore, nothing stands in the way of producing in the Colonies as much alcohol from wash as the English distiller does, thereby effecting a great saving in fuel and labour. In consequence of such improvements the fermentation would be very rapid; and in consequence of this rapidity, the formation of acetic acid in the fermenting vats would be reduced to a minimum.”

“This, I conceive to be the sum and substance of all possible improvements in the manufacture of rum, abstracting, of course, from consideration the apparatus employed in distillation. Let designing people victimize the colonial distiller; their “arcanum,” if worth anything, will always be reducible to the principles here laid down.”

“While on the subject of rum, I may just as well speak of a fact which has puzzled many a planter.”

“It is well known that two contiguous properties, having the same soil in common, pursuing the same process of manufacture both for sugar and rum, having similarly arranged still houses, will yet produce rum of very different quality. There used to be many such cases, whether there are any now I cannot vouch for. If there are, let the fermenting vats of the two properties be measured carefully, and then compare the number of square feet of surface of the wash exposed to the air to the whole contents of the vat expressed in cubic feet, and compare the result obtained on each property. The vat which exposes the largest surface of wash, compared to the contents, will yield the finest rum; at least I have reason to think so.”

“As my object is not a scientific treatise on distillation, but simply a description of how Jamaica rum is made, the following quotation, showing how it was made during the last century, may prove interesting.”

“D. Dallas’ History of the Maroon War’ is one of the most interesting works treating on West Indian subjects. It should hold a conspicuous place in the library of every Jamaican. It was published in London by Longman and Rees, 1803, is now a scarce book, and well merits being reprinted, even at the expense of the colony. In mentioning the cane and distillation of rum, he says :—The bounty of the cane ends not here; the very dregs and feculencies of this viraluable plant yield one of the purest, most fragrant, and salutary spirits in the world. To enter minutely into the mode of making rum would be unnecessary, the business of distillation being so well known in Europe, and a brief account of the component materials and peculiarity of process will be sufficient. To work the stills and worms, it is necessary to have a cistern for dunder (a term applied to the lees, or feculencies of former distillations, which have a most offensive smell), another for scummings, and a number of fermenting vats or cisterns, each equal to the contents of the largest still. In Jamaica, cisterns are made of plank, fixed in clay, and are universally preferred to vats, or moveable vessels, for the purpose of fermenting. In the British distilleries, these fermenting cisterns are unknown. They are not so easily affected by the change of the weather, nor so liable to leak as vats, and they last much longer. The ingredients used for procuring rum consist of molasses, scummings of the hot cane juice from the boiling-house, or sometimes raw cane-liquor, from canes expressed for the purpose; lees, or dunder; and water. The use of dunder is to produce fermentation. These ingredients being well mixed in the fermenting cisterns, and pretty cool, the fermentation rises in the course of twenty-four hours to a proper height for a charge of molasses, when three gallons for every hundred of fermenting liquor is added to it; and a second similar charge is given in a day or two after, when the liquor is in a high state of fermentation.”

“When it grows fine, and throws up a few clear heads, or air globules, it is fit for distillation, and conveyed into the largest still, where it is made to boil. In about two hours after, the vapour, or spirit, forces its way through the worm in a stream as clear as crystal, and it is suffered to run till it is no longer inflammable. The spirit thus obtained is called low wines, and to make it into rum of the Jamaica proof, it must undergo a second distillation.”

“The proportion of rum to the crop of sugar is commonly estimated in Jamaica as three to four; but this is said to be too great an allowance on a general estimate, and that two hundred gallons of rum to three hogsheads of sugar, or two-thirds rum to the crop of sugar, is nearer the truth.’”

Distillation is carried on in Jamaica with a good deal of practical, if not with much scientific knowledge; but each bookkeeer has his own theory, and some are more successful than others. A bookkeeper who makes a good rum crop, and is otherwise active and intelligent, soon finds himself on the high road to promotion. A disinterested person might ask—Does it pay? But “Old Jamaica” being “par excellence” the rum, and my present object to describe how it is made, we will leave all financial topics for a future opportunity.

The stills vary in size, but on most estates contain one thousand gallons, and some properties have two such stills. At Wakefield, St. Thomas in the Vale, there are two of fifteen hundred gallons each. There are a few improved stills in the island, and lately a continuous still has been introduced; but the generality are the old-fashioned common stills, with manhole door, charging hole, moderately high goose neck, and two pewter or copper retorts; the larger retort to contain the low wines is that next the still; the smaller one, between the first retort and the worm tank, is for high wines. The goose neck of the still passes down nearly to the bottom of the low wine retort; being perforated with small holes for about ten inches, from the bottom up, care should always be taken to put sufficient low wines in this retort to cover these holes. The goose neck connecting this retort to that containing the high wines should pass down almost to the bottom of this, and should also be perforated.

(To be continued.)

The vat-rooms, as I have invariably found, are kept very clean. I have visited many; some are more convenient than others—that is, more attention has been paid to facilitate the work. The vats are made to contain about two hundred gallons more than the still, so as to leave sufficient space for fermentation. The mixing cistern is a wooden box, or bin, generally made of country wood, strongly bound together, and in most instances made to contain sufficient wash for two vats. This is generally placed in a hole in the ground; sometimes, and more properly, in a walled pit, with sufficient room between the wood and mason work for a person to enter freely, and a pump is usually placed on a platform above the cistern, and throws up the wash to a canal, which distributes it to the vats, or butts. There is usually a cistern for molasses, another for skimmings, and frequently that for settled, or clarified dunder, is also in this room; they are all so placed that their contents can be run down to the mixing cistern.

Great care is taken to prevent acidity entering these cisterns; when emptied they are washed and white-washed, as are also all the canals or gutters, and this white-wash is dry rubbed off before they are used; this attention is particularly required for the skimmings’ cistern. This cistern is connected by canals to the boiling-house. The dunder cistern, be it placed inside or outside the vat-room, is merely a receptacle for a sufficient quantity of subsided dunder, where it may be kept cool and ready for service. Once the mixing cistern is properly started, it is never pumped dry, but from fifty to one hundred gallons are always kept in it to serve as a ferment for starting the wash. On most estates a mud-vat is kept; this is frequently placed in the can-room, or some out-of-the-way corner. There are many opinions on the utility of a mud-vat; all, however, agree that the best flavoured rum is produced from it.

[The mud-vat becomes in following years the infamous muck hole and even though we see so much common clean rum being made in these papers, we understand it is important to flavoured rum from the beginning.]

In the most convenient place, generally above the can-room, on a strong platform, are placed two puncheons, one for high wines, the other for low wines; these are connected to the retorts by copper or pewter piping and brass stop-cocks, through which the puncheons empty themselves into the retorts. The lees from the retorts are by some distillers run into the dunder cistern; others object to this. For my own part, I cannot see the utility of it, all the spirit having been extracted from the high and low wines in the previous stilling; the lees remain with an unpleasant acrid smell and taste, and must deteriorate the dunder. In draining off lees from the retorts, or dunder from the still, care should be taken to open the vent-cocks. I have seen several times both retorts and stills collapse from want of due attention to this.

[More consensus on the idea that particular volatile acids can spoil the dunder.]

On drawing off the dunder to the first cistern below the level of the still, it is allowed to settle as long as possible, and only the subsided dunder is pumped to the cistern or cisterns placed at the higher level; this should have particular attention. The dunder should never be used in the mixing cistern till it is cold, and, if richer than 4° Baumé [SG 1.028], should be reduced to this density with water. If the dunder is not subsided, it would show a greater density than it really has, and too much sediment would accumulate in the wash.

Dunder may be preserved from one crop to the other by paying attention to prevent acidity, and many distillers do keep it, removing any acidity before crop by boiling it in the still with wood ashes. I should prefer starting with everything clean and fresh, as skimmings, if properly used, are a sufficient ferment to start with; and although the first distillings may not give a very high return, nevertheless all chances of acetous fermentation are thus avoided, and if the vats are sluggish to start, hot bricks may be thrown in, together with some alum. In distilling, care should be taken to run off all the low wines before drawing down the dunder. It is a decided loss not to do so; any low wines left in the dunder renders this too rich for fermentation, and water has to be used. A good return from one thousand gallons of wash would be—

[A lot is going on here! For starters, we see more details on how dunder could be evaporated in the still to remove volatile acidity and better prepare it for reuse. First they drive off any value in the low wines retort into the high wines, and then proceed to drive steam from the wash into the low wines retort. I do wonder if this would ever be conducted with the manhole cover opened. We also see the goal for common clean rum to have dunder that is as clean as possible and simply ladden with lactic acid as opposed to any volatile acids. The clean in common clean starts to look a little different and resembles clean process rather than clean distillate. I continue to suspect that there fear of an acetous fermentation is more than aerobic acetobacter and also entails anaerobic lactic acid bacteria that can produce acetic acid as well as lactic acid.]

[I’m assuming all these numbers are over proof, but the interpretation is not obvious to me. It appears to be the range of 65-70% ABV. Anyone else’s interpretation is appreciated.]

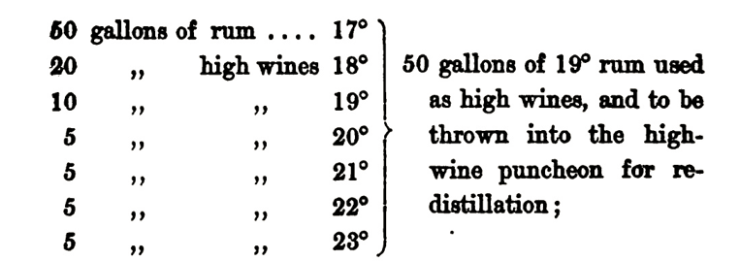

and about 100 gallons of low wines—that is, from 24° to water making low wines, or a mixture of about 29°, this is for the low-wine retort; but such a return as this can only be expected after the vats are in good working order, and during the favourable season. In commencing crop, the first distillation is expected only to give low wines; the second, both high and low wines; and the third, spirit.

[A fascinating note at the very end, but it almost sounds obvious now that you think about it. I’m suspecting for these low wines the author is implying under proof and that is why 29° can be the average of 24° to water (and why it is said as water and not zero). 24° UP would be about 43% ABV and 29° UP would be just over 40% ABV.]

One of the objects of most importance is to have a good supply of running water to the worm-cistern, and, through a tube, this should be conducted to the bottom of the cistern, and to the end furthest from the overflow; thus the warmer water will be constantly flowing out. Some stills have refrigerators; they are a double set of six or eight pewter tubes, about four feet long, let in between the goose neck of the retort and the worm; a shower bath is kept constantly on it, the water falling into the worm tank. Pewter worms are certainly the best, though many are made of copper piping, and four inches diameter; they are frequently over 200 feet long, coiled to the shape of the worm tank, and making two or three turns before discharging into the can-pit. They are supported by double hardwood posts pinned together, having holes morticed to receive the tube (logwood is the most durable in water). This method is a great improvement on the old-fashioned spiral worm, bound together by clamps of pewter. The inconvenience of copper worms is, they are apt to produce verdigris inside when not used for some time, and the first rum may be injured.

[The idea of a refrigerator may best compare to what I’ve seen called a brandy ball and adds a degree of reflux to a pot still without adding a plate. These may have been what the author was referring to earlier as improved stills.]

Whilst on this subject, I will mention a circumstance which came to my knowledge many years since. In the neighborhood there were several cases, and some fatal, of what to-day would probably be called Asiatic cholera. It was noticed these occurred among the labourers working on a certain estate, and of these, those habituated to rum drinking. Finally, it was found that the rum contained lead-poison, and, on investigation, that, in repairing the worm, the piece which passed through the mason work to the can-room, worn out by age, had been replaced by a piece of lead pipe; this was removed, and there were no more cases of the kind.

[Recently, I came across an anecdote describing how Ben Franklin brought this to the attention of distillers in the colonies. Boston went through its lead tainted rum phase. Franklin’s experience with lead as a printer gave him the experience to diagnose the problem in the distilling industry. I did not realize that so much pewter and lead was used and wondered if every producing region went through a tragic lead phase.]

On the estate where I have had the best opportunity to observe the process of distillation, the book-keeper (Mr. J. C. Thompson) is a Jamaican; he knows his business thoroughly, and his return of rum has been the best I have seen. I shall therefore confine myself principally to what I have seen him do.

[J.C. Thompson may be the Jamaican equivalent of Uncle Nearest and possibly the first black distiller to be recognized with such esteem. The name begs more research and because I don’t know enough about the topic I’m making big assumptions that earlier distillers were of European descent. It seems an aspect of the history we should know.]

At the commencement of crop, the vat-room was cold and damp, not having been used for some years. For some days previous to setting the wash he kept up a fire night and day, till the walls dried, and the temperature rose to 80°F=27° Centigrade. I had sometimes seen the thermometer as low as 14° Centigrade, and at that season of the year—January—felt quite relieved when the sun rose over the mountains and warmed me.

The butts capable of holding 1000 gallons were set to 800 gallons, the size of the still. These butts are five feet high, seven feet diameter at bottom, and six at top, painted outside, and having brass discharge cocks; they are made of cedar plank, bound with strong iron hoops, and said to have been in use over forty years. They had been some eight or ten years out of service, and when the estate was put under cane cultivation again, by its present owner, they were found to be perfectly good. These vats, when filled with wash, are left uncovered. The vat-room is spacious and well ventilated, but the temperature is maintained as near as possible at 80°F. The wash, when once pumped into the vats, is never touched, —neither skimmed nor stirred. All the filth gradually sinks to the bottom; but when being discharged into the still, a man gets into the vat before it is quite empty, stirs up the residue and washes out the vat, or rather scrubs the sides and the bottom, using the liquor or wash, but never water. Fresh wash from the mixing cistern is pumped up as soon as possible; should there be none, the vat is swabbed out, and, if likely to remain out of use for a day or two, it is whitewashed; but before being used this is carefully dry rubbed off. Let Windward Island planters bear in mind what is here repeated,—the fermenting vats remain uncovered, are never skimmed nor stirred.

[The authors seems to deliver this is a solemn way where this has been handed down from a true master distiller, Mr. J.C. Thomas.]

The mixing cistern is in the center of the vat-room, sunk into the ground. It holds over two thousand gallons, and during crop is never emptied; about 100 gallons always remain in the bottom, and when by chance distilling may have been suspended for a week or two, I have always seen Mr. Thompson pay particular attention to the ferment in the mixing cistern, giving it from time a small dose of molasses to keep up fermentation. A great deal of carbonic acid gas is evolved in this cistern, and it would be dangerous to enter it. The advantage of having it placed in a hole larger than itself is, that if it leaks when full, and this does not soak back into it when empty, which frequently happens when it is surrounded by earth : this becomes saturated, and there is a constant ebb and flow, causing a commencement of acetous fermentation in the wash.

[This was not quite spelled out in previous descriptions. The mixing cistern is a vat in a pit, but there is an open space around it where it can leak gently or be serviced. It is not backed by clay like other sunken fermenting vats. The author connections this construction strategy to that of undesirable bacterial fermentation.]

The dunder cistern is a large wooden tank; it is cleaned out thoroughly once a week. Only the subsided dunder is pumped up to the upper cistern: this is a shallow but large wooden bin. Professor Hoffmann says—”Large, shallow tanks are the best for dunder. Dunder contains ferment inert, but by exposing it to the action of the oxygen of the air the albuminous matter undergoes a change which restores in a great degree the power of producing fermentation.”

Dunder, when subsided, should be of a bright brownish colour, have a pungent rich smell, and bitterish taste; should only be used cold, and if of a greater density than 4° [SG 1.028] should be reduced by adding water to it before being run into the mixing cistern.

In Jamaica they use Arnabold’s saccharometer; three degrees are equal to one of Baumé.

The quality of the molasses is an object worth consideration. Some persons object to fresh molasses, as being less ready to ferment; but it is well known that molasses taken from a tank where fermentation has been going on for weeks, or months, has decreased in density, and will therefore take a greater quantity to saturate a given number of gallons of wash to a certain degree of density.

The skimmings bent down from the boiling-house should be used up as soon as possible; all the dirt that has come down with it, and which on being left quiet forms a thick cake floating on the top, should not be taken off and thrown away. This is the matter which produces fermentation; it should be thoroughly stirred up, and carefully run down to the mixing cistern.

Planters who wish to make good rum crops should be careful to collect all the sour canes from the cane fields; the suckers and plants,—in fact, no portion of the cane unfit for sugar should be lost. If not required for the stock, the leave’s only should be cut from the plant, and all the rest should be passed through the mill. The juice from the tops, suckers, and rat eaten canes make the best of rum. It is this and the skimmings, and very frequently cane juice, which produce the “Old Jamaica.” Molasses, dunder, and water merely make spirit. The question may suitably be asked: If in the anxiety to make Old Jamaica, parties who have to do with it may not at times sacrifice a greater value of good cane-juice than the Old Jamaica may be worth, much to the injury of others’ pockets, who chuckle over the value of their rum, simply because they are unable to know that the ingredients used were in themselves of greater value than their boasted rum. It must, however, be conceded that on an estate there always must be a great deal of refuse that can only be turned to advantage by distillation; rat eaten and wind broken canes, suckers, tops, and bruised canes, all unfit for sugar, will, if constantly and carefully collected, make a great deal of very fine flavoured rum; washings of tanks and apparatus, the coarser part of the skimmings, etc., but whether it pays to run good cane-juice to the liquor cistern, instead of converting it to sugar and molasses is to me a very problematical question; that this is done, however, cannot be denied. Bookkeepers are expected to make heavy rum crops; the more rum made in proportion to sugar shipped, the greater their merit.

Nine-tenths of estate owners would call to account an overseer or bookkeeper who did not make the same proportion of rum to sugar that his predecessor did; and very probably the bookkeeper, the the overseer, or even the attorney himself would lose his situation; consequently, it may be feared many pay too dear for their whistle. However, if people have their hobby and like to ride it, it is not my business,—by all means canter away, and get your “Old Jamaica,” without regard to cost.

However, to return to rum making. The ingredients should be thoroughly mixed in the cistern with the previous ferment, otherwise the heavier will sink to the bottom, and the two vats (if the cistern holds wash for two vats) will be of a different density, and one will take longer to attenuate than the other. The wash is usually set at 22° to 24° Amaboldi, 7-1/3° to 8° Baumé [SG 1.053-1.058], and attenuate to 7° or 8° Arnaboldi=2-1/3° to 2-2/3° Baumé [SG 1.016-1.018]. To reach this attenuation they take generally 48 hours, sometimes but 36, and never more than 56 hours. In no single instance have I seen them take longer than this in the distillery which Mr. Thompson superintends; in some others they take four days.

The system of thoroughly mixing the wash in the cistern, and then pumping it to the fermenting vat, appears to be far superior to that of mixing in the vat itself, as is done in most islands; much time is saved, a better mixture is made, and a quicker fermentation is produced. In most, or all the distilleries I have seen before coming to Jamaica, the fermenting vats were skimmed and thoroughly stirred once, and very frequently twice a day, and kept carefully covered with matting, or a board cover; all this is certainly much unnecessary trouble. By being careful to use subsided dunder, only the feculencies which come into the wash with the rum—cane juice, the skimmings, and the molasses, are acted on; they sink to the bottom of the vats, and no doubt, by being stirred up and mixed thoroughly in the wash as it is being run into the still, and boiled there in the liquor, they help to give that peculiar rich flavour which Jamaica rum possesses. Moreover, take two vats of equal density, skim and stir one, do not touch the other, and that in repose will attenuate much more quickly than that which has been skimmed and stirred. Wash attenuates best where the vat-room is kept at an even temperature and well ventilated and light, but not when a strong current of air passes over the vats, giving a quicker and better return, when distilled, than wash that has been set up in a dark and badly ventilated room. An estate in St. Thomas-in-the-East had a badly-ventilated liquor loft, and the return of rum was not good. By accident this was destroyed by fire, and a temporary open shed was fixed up for the vats. The mode of mixing was the same, but the return of rum was now much better. One of the best returns of rum that has come under my notice is on an estate where the vat-room is thoroughly ventilated. Many vat-rooms have a flooring so placed as to facilitate walking round and inspecting the contents of each vat; all should be so made.

The still and retorts should be thoroughly scoured once a week. Nothing cleans copper better than a wad of guava bush and some sifted megass ashes [megass = bagasse]. Distillation should proceed slowly and regularly, maintaining always an equal thread of spirit running from the still; uneven runnings waste the spirit, and give it at times an inferior flavour. Great attention should be paid to the water in the worm-cistern; the colder the temperature at which the spirit issues from the worm, the better its flavour, and more spirit is obtained. I have seen several stills where a very considerable loss must have accrued from a scarcity of water on the worm; not that the fact was not recognized, but from an absolute scarcity of water. Leaky joints are sometimes met with, or a man-hole door badly fitted, and much spirit is thus lost. The readiest made cement to stop such leaks is fresh cowdung and temper lime.

The mud-vat is kept to receive all the refuse about the still and liquor loft, any thick muck that may be taken from the bottom of vats or canals, refuse, low wines, washings, sweet filth of every kind. The mud-vat, by being added to daily, is kept in constant fermentation; it is the general receptacle for every kind of fermentable matter that would otherwise be thrown away. When filled sufficiently to contain a stilling, it is let down to the still; no attention is paid to its attenuation. Distillers say the best flavoured rum is made from the mud-vat, but, as its contents are a thick slushy stuff, care must be taken that the still does not burn. Many planters object to the mud-vat on this account. The dunder must be thrown away, and dunder cistern and still thoroughly scoured after a mud-vat stilling.

Colouring a puncheon of rum is supposed to reduce its strength one degree. In each can-room a clear phial filled with coloured rum is kept as a standard or guide. The colour barrel or puncheon is placed in the can-room. Most distillers say old colour is preferable to new, and some make it one year to serve during the next. A small calabash, made to hold the quantity sufficient to colour a can, or five gallons of rum, is fixed to the end of a stick, and each can is coloured and compared with the standard before throwing it to the butts or puncheons, as the case may be. This appears to me the surest method of colouring; some do it in the butt or puncheon, but they do not always hit the mark.

A great deal depends on the colouring, and many distillers are not good colour makers. It requires practice.

The best sugar should be used, and as dry and free from molasses as possible. I was once present when a planter came to show a bookkeeper how to make colour. He made a signal failure. I was told of a circumstance that happened on an estate in Vere. They could not make good colouring; the rum was always cloudy. On the adjoining estate, famed for bright coloured rum, the colour maker there was requested to come and see what he could do; he refused, but offered to make the colour if they sent him the sugar. It was sent, and the colour spoilt. Then a barrel of sugar was taken from this estate to the other, and then it made first-rate colour; consequently, it was presumed the fault lay in the sugar. Since this they always melt the sugar, clarify the syrup, and reduce it to colour. Previous to hearing this circumstance, several distillers had told me this was the best mode of making colour. The difficulty is to give the sugar the dark bright colour without burning it; yet if it is not a sufficient time on the fire it will give a cloudy hue to the rum.

The method adopted by Mr. Thompson was as follows: Into a copper pan, shallow and wide,—the lower part of a copper-tache,—he put about eight gallons of good dry centrifugaled sugar, and with a brisk but not strong fire underneath, and a man with a long stick stirring the sugar constantly round in the same direction, the sugar dissolved and began to froth. The whole operation did not take over fifteen minutes. Gradually a kind of purple ring formed on the froth of the boiling sugar, and round the edge of the pot; then the stirring had to be more rapid, the ring increasing in size and the brown center diminishing; the man stirring at first round the edge and to the bottom, gradually decreased his circle as the brown spot decreased, until the whole pot presented one uniform colour a dark brilliant purple. Immediately the fire was extinguished, about a gallon of water poured gradually into the pot, the stirring continuing all the time; then half a gallon of strong rum was added in like manner, and the colour was of the best I have seen. It is evident to me that sugar which may have an excess of lime will make bad colouring, and sugar made from juice from which the feculencies have not been removed cannot make good colouring. Cloudy rum can be made bright by adding to the puncheon a batter of clay and vinegar.

Most rum cellars have large butts connected to the can-room by pewter pipes, stop-cocks, and pump. The rum, after being coloured, is pumped up into these, from which puncheons are filled as required. On a large estate where much rum is made, this is very convenient, and saves a good deal of labour, and the rum is not so exposed as when headed up in cans.

The flavour of rum, as well as its smell, must depend in a great measure on the ingredients used. Molasses from well-made sugar has a rich aromatic smell, which it also imparts to the wash. Skimmings and cane juice used freely in a liquor loft produces the best quality of rum. The query is—Does this pay? I remember an old gentleman in the Windward Islands who had always an acre or two of Creole cane, out of which he yearly made rum for himself and his particular friends. He considered the juice of the Creole cane produced a superior rum. These canes are short-jointed, small, and soft, and the juice is peculiarly aromatic; by many it is supposed these canes are indigenous to the West Indies. The best flavoured rum I have ever tasted was made from cane juice, skimmings, molasses, and water. It was forty years old—yellow from age, but not coloured, and, looking at it in the glass, might have been mistaken for oil; but such rum as this could not be bought, neither would it pay to make it for sale.

For myself, I have not the slightest doubt the very best rum is made when no dunder is used in the ferment. In making rum for any very special purpose, I never hare used dunder; it, however, helps to make quantity, and very good rum is made where dunder is liberally used. The rum I have seen made is peculiarly good, and on that estate no water is ever used in the mixing cistern, unless it may be the sweet water from the coppers on boiling-off day, and the washings. The usual mixture is 480 gallons dunder, 280 gallons skimmings, and 40 gallons molasses. These 480 gallons of dunder at 4½° Baumé [SG 1.029] would represent 2160° density, or 54 gallons of molasses. That is, do not use dunder; to produce a wash of 22° to 23° Arnaboldi, such as the above mixture would make, you would probably get less rum, after taking a longer time to attenuate, and would be the value of 54 gallons of molasses out of pocket. From this mixture, in January, on an average of stillings, I saw obtained 43.75 gallons of 17° [67%ABV], or 5.46 % on wash distilled; towards the end of February, 48.33 gallons per still, or 6.04% on wash distilled; at the same time, but with a smaller proportion of skimmings, more dunder and molasses, 42.22 gallons per still, or 5.27% on wash distilled. All the vats which gave this return attenuated in thirty-six hours. Estates which convert all their molasses into rum cannot possibly have skimmings to mix constantly in their wash. Sugar making is liable to interruption, but rum making continues as long as there is molasses in the cistern. Wash that has a fair proportion of skimmings attenuates faster, and gives a better return than when made of dunder and molasses alone. Proof:—On the 26th February, 100 gallons molasses, 1500 gallons of dunder, 13° Arnaboldi, 4-1/3° Baumé [SG 1.031], were mixed in the cistern with about 50 gallons of fermented liquor, and pumped up to two vats, leaving in the cistern the same quantity of wash for ferment. These vats were distilled on the 1st March, or after fermenting fifty-six hours. They had been set up at 7-2/3° Baume [SG 1.055], and had attenuated to 5° [SG 1.036]; wash made with dunder and molasses alone seldom attenuates below this. The 1600 gallons wash gave 70 gallons, 17° rum [67%ABV], or 4.37% [This is not the ABV of the ferment but the percent output to input so the ABV of the wash is 2.93%]. On the 27th February, molasses being scarce, 80 gallons molasses and 1520 gallons of dunder were mixed and pumped up to two vats. These were distilled on the 2nd March, giving 65 gallons of 17° rum [67%ABV], 50 gallons high wines 25°, and 60 gallons low wines. The residue in the mixing cistern, after these dunder and molasses mixtures, was not so active, and the average strength of the high and low wines decreased at each distilling.

Mixtures made with dunder and molasses alone can, after attenuation has ceased, remain a longer time without injury or decreasing in their return of spirit when distilled, say even fortyeight hours; but vats set up with a good proportion of skimmings would probably spoil by that time; acetous fermentation would have commenced, and the sooner such wash is distilled after attenuation has ceased, the greater the return of spirit will be. Wash made with cane juice or skimmings, properly proportioned to the other ingredients, will attenuate in thirty to thirty-six hours to 1-2/3° Baumé [SG 1.011], and be ready for the still. Wash made of dunder and molasses alone will take forty-eight to fifty-six hours, and will only attenuate to 15° Arnaboldi, 5° Baumé [SG 1.036], and the return of high wines (that is, spirit from 18° to 28°) is less, the head cuts sooner.

With but few exceptions, all the distillers with whom I have conversed say they obtain 5% of 17° rum [67%ABV] for wash distilled [5x.67=3.35% ABV for the wash unless I’m misunderstanding the math.]; but, on referring to books apparently very carefully kept, it appeared to me that, on one estate, they had distilled 505,000 gallons wash, and made 21,940 gallons of 17° rum, or 4.35% on wash distilled. Again, on another, 459,000 gallons wash had made 20,400 gallons 17° rum, or 4-5% on wash; in another instance, 464,000 gallons wash had made 21,130 gallons 17° rum, or 4.55% on wash. The quantity of rum does not appear to be increased by the vats taking longer to attenuate. For instance, in the month of April, vats taking from four to four and a half days to attenuate, being set up at 21° Arnaboldi, 7° Baumé [SG 1.051], temperature varying from 89 to 94, vats attenuating to 3-1/3° [SG 1.024], the return on a series of distillings was 4.63% on wash. But again, if a quick fermentation is forced by a high temperature in the liquor loft, fermentation ceases before attenuation is completed, and the yield will be poor. I think, on every 1000 gallons of wash distilled, 10 gallons of 17° spirit ought to be obtained for every degree Baume that the wash has attenuated, and most distillers with whom I have conversed assert this. That the object of the distiller should be so to rum the wash, that the vats may attenuate to the lowest possible grade: there is no doubt the lower the attenuation, the greater the proportion of spirit obtained. Old planters assert that the most and the richest flavoured rum is made from wash set up sweet and attenuated slowly. They say the best Jamaica is made on estates that make proportionally but a small quantity of sugar. The reasons they assign are, that on such estates the liquor loft and cisterns are in proportion to the crop, and nothing is hurried, whereas on estates which have increased their sugar crops, without proportionally increasing their distilling plant, they have to adopt a quicker method, so as not to be overcrowded with an excess of skimmings and molasses in their cisterns. Mr. Thompson does not permit a vat to remain more than fifty-six hours from time of being pumped up till it was passed to the still, and even such a length of time is very unusual.

(To be continued.)

One of the gentlemen from whom I hare gathered a great deal of information—Mr. Ellis, of Moorlands Estate, Vere—who shows also a good average return of spirit for wash distilled, has his liquor loft and stills in particularly good order. The vat-room is light, from having glass windows; it is well ventilated, and extremely clean. He advocates, in common with Mr. Thompson, the use of cold dunder and cold skimmings, and particularly objects to that hurrying system of forcing hot ingredients into the mixing cistern. His mixtures for an 800-gallon still are as follows:

[SG 1.086]

This attenuated in 18 days yielding 30 gallons of spirit = 34.50 gallons of 25° or proof rum, or 11.50% on wash distilled. [11.50X.57=6.56% ABV wash.]

[SG 1.076]

This attenuated in 11 days giving 25 gallons of spirit=28.75 gallons of 25° or proof rum, or 9.58 per cent. on wash distilled.

It is stated that very frequently at the commencement of crop it is difficult to start the vats. This difficulty, however, has not been experienced by myself, and, where it has arisen, it may probably be traceable to want of care in tempering the liquor. As Basset says—”Il convient d’aciduler la melasse même puisque les alcalis qu’elle renfermo (9 a 10 p. 100 environ) produiraient une influence nuisible sur le resultat en s’opposant á la régularité de la fermentation.” [It is advisable to acidify the molasses itself since the alkalis which it contains (9 to 10 p. 100 approximately) would produce a harmful influence on the result by opposing the regularity of the fermentation.] [Basset gets referenced again later with the title of the text: Guide Pratique du Fabricant de Sucre.] It is a very common thing to see cane juice over-tempered at the beginning of crop, and both skimmings and molasses having an excess of lime are run to the mixing cistern. This excess of lime retards fermentation, and if, added to this, the whitewash on cisterns, canals, and vats had not been dry rubbed off, probably the wash would, by the time it reached the vat, contain so much alkali as to prevent fermentation.

Boiling molasses with sulphuric acid converts it into grape sugar, and makes a good yeast.

Cane tops—that is, the plant and top without the leaf, cut up in a top cutter—if spread three or four inches deep in the mixing cistern, and allowed to remain there twenty-four hours after having had a puncheon of molasses mixed with it, makes an excellent ferment, imparts a fine flavour to the wash, and destroys any acidity that might be in the mixing cistern. I invariably inquire of all practical distillers if they think the weather affects the yield of the wash. They all agree that it does, more particularly a thunderstorm. On one occasion, some years ago, at Ponce [Puerto Rico], we had been distilling a number of vats, getting a good return; the vats had invariably taken about fifteen days to attenuate; they had had the same mixture, and had given the same number of gallons of spirit; a heavy thunderstorm occurred one afternoon, and the vats distilled the next day gave but little rum. For those who wish to make comparative calculations, I may add, the still contained 300 gallons. On one occasion I had the curiosity to measure, gallon for gallon, the molasses and skimmings, and weigh the sugar produced from 57,500 gallons of cane juice; the result was 56,000 lbs. sugar, 2317 gallons molasses, 2455 gallons skimmings; the molasses and skimmings produced 2397 gallons of 25° rum [71.43% ABV]; the best return was 10% of proof rum on wash that took from fifteen to eighteen days to attenuate [5.7% ABV ferments], having been set up at 11½° Baumé [SG 1.086]. This would equal about 7½% of 17° , or 40° overproof [80% ABV]. Other vats, set up at 10½° Baumé [SG 1.078], took ten or eleven days to attenuate, and gave 8.30% of 25° proof rum = 5.4% of 17° [This gets odd and we can only deduce that the first number is under proof while the second is over; 42.86% ABV, 66.85% ABV respectively]. The proportion of skimmings on cane juice was very small—only 4.27%; but this was owing to the great care taken on that occasion in skimming the grand copper. I had previously stated I was convinced less liquor was wasted by using the skimmer than by using the rake to draw off the skimmings, and I was careful to prove it, and personally superintended the skimmings of each copper of cane-juice.

[Illustration borrowed from Leonard Wray, 1848]

A large quantity of Jamaica rum is shipped to Germany; a mercantile house in Kingston doing an extensive business in this line employs tasters, who travel about the island, pay a good price, and purchase that which they think adapted for that market. Distillers who wish to give this peculiar flavour to their rum use the following receipt:—Take 100lbs. of yellow clay; this, with 5lbs. of finely pounded brimstone, is thoroughly mixed in 10 gallons of low vines, to which are added 70 gallons of thick muddy skimmings, care being taken that the clay is thoroughly dissolved in the low vines, so that the mixture may be complete; to this add 4lbs. of balm or fever grass (Spanish, “Lemoncilla”; French, “Citronelle”); the whole is placed in a puncheon to ferment, and after fermentation ceases it is fit for use; in fact the longer it is kept the better the effect it produces; two quarts are to be thrown into the low wine, and one quart into the high wine retort; when the rum first begins to run it has a very unpleasant smell and taste, which however gradually disappear. This rum sells remarkably well, and distillers who produce it of the right flavour are generally rewarded by their employers.

[I get the feeling that this paragraph is a bit of a hoax.]

It was generally supposed that the use of sulphurous acid gas as a defecator for cane-juice would have a prejudicial effect in the liquor loft; so much as this a preconceived idea, that a planter in St. Thomas-in-the-East told me he had some years past used sulphur in his boiling-house, and the result had been most disastrous on his rum; another on the north coast had experimented with sulphurous gas (or more probably with sulphuric acid), and his rum had been notoriously bad; consequently, although I felt convinced “Stewart’s Process” would more probably improve than deteriorate the rum crop, I was curious to see the result. Stewart’s apparatus was worked by myself at Rock River estate in the early part of March; the sugar was much superior to what had previously been made there, but having to return to Kingston I did not see any rum made until the 26th March. I was surprised on nearing the still to find an unusual rich, mellow, fruity aroma proceeding from the dunder, and on entering the liquor-loft a different odour from the usual one was perceptible. On mentioning this to the distiller he told me there had been a marked improvement in the fermentation in the mixing cistern and vats since the sulphurous acid gas had been used in the boiling-house; that he found the vats took a few hours more to attenuate, but that the vinous fermentation was richer. He pointed out the vats; the odour from them was peculiarly rich, fermentation was different and stronger; there was a rich thick crust on the liquor, under which fermentation was proceeding rapidly, and the air bubbles possessed that peculiar purple tinge, which is a sure demonstration of a healthy vinous fermentation; at times the thick frothy crust breaks, and rushes as it were to the side of the vats and gradually forms over the whole surface again. So convinced has Mr. Thompson become of the advantages to be derived in the still-house from the use of sulphurous gas in the boiling-house, that he is always very attentive to have the juice expressed from the rum-canes thoroughly fumigated. There is one fact that cannot be contradicted—the rum made at Rock River estate is of the best, and the return on wash distilled has been on the whole crop 5.23%.

That sulphurous acid gas should produce good results on the juice of sugar canes can be easily understood; the gas checks acetous fermentation, and encourages the vinous one in such juice; moreover, in good cane-juice the gas acting as a defecator separates all the nitrogenous matter from the juice; it is caused to float on the surface, and is removed as skimmings; naturally, therefore, such skimmings must, being particularly rich in nitrogen, form a strong ferment in the wash made from it.

The great object of the distiller should be so to combine the ingredients used in the mixing cistern as to produce the speediest and most perfect attenuation which will produce the greatest quantity of spirit. To prevent acetous fermentation from encroaching in the loft (a sure sign it has commenced is when the vats throw up small, bright, and sparkling bubbles, and there is little or no attenuation), a pound and-a-half of alum dissolved and added to a thousand gallon vat, a pail of clean, sifted wood ashes will cut the acidity, and produce vinous fermentation; a lye from the ashes of a burnt wood-lice nest will act more readily.

[This lye leached from the ashes may be KOH. I’m not sure how the nest factor increases the quantity of lye formed.]

No doubt is left on my mind that the peculiar racy flavour of Jamaica rum is principally owing to the quantity of skimmings used. But is this so-called skimmings not in reality cane-juice that ought to have been converted into sugar? The quantity of skimmings varies with the quality of the cane-juice; however, 7% of skimmings on juice extracted is a very fair allowance, taking into consideration all classes of cane; 4 to 5% is sufficient for good juice alone; any quantity of skimmings thrown to the mixing cistern exceeding 7% on gross quantity of cane-juice ground is so much taken unfairly from the sugar crop, and sugar has been by many made subordinate to rum, without paying the least attention to the real money value of the ingredients used.

The French usines convert most, if not all, their molasses into rum; but it is molasses from the second and third jet, rich in fermentable matter, but poor in sweets; with this they only use the dross of their skimmings from which the cane-juice has been extracted by filtration; with the washing of the apparatus used instead of pure water, their returns, on molasses used, varies considerably, but in the best conducted usines may be be calculated at 70% of proof rum, 25° and 10.50 % wash distilled; they use the continuous stills, both Derosne’s and Savalle’s, and make a very pure spirit, but it has not the flavour of Jamaica rum. I think in those usines they might most advantageously to themselves and to the planters, their adherents, purchase from the latter all their rat-eaten, damaged canes, suckers, and plant tops, to grind for cane-juice for distillation. When I was in Martinique one of the directors made me a present of a quarter cask of usine-rum ; on my return to Puerto Rico I put some raw beef in it, added some dried prunes, and a short time after most persons drank it as brandy.

A very mellow flavoured spirit can be made by putting about 5lbs. of salt, 5lbs. of lime, with a bundle of shavings of the guava-root, all tied in a cloth and hung in the wash in the still during distillation; the rum comes over having a very oily pleasant flavour. In some of the whisky distilleries they leave a small slit in the side of the still, which is covered when the still is at work to prevent escape of spirit, but through this slit, just before the wash begins to boil, they insert a small piece of brown soap. A small quantity of spirits of ammonia, about half an ounce to a puncheon, removes that acrid unpleasant taste which almost all new-made rum has in a greater or less degree; the same quantity of sweet spirits of nitre softens the flavour of rum, most fruits improve it, the pineapple and the mamé apple especially so. Rub a glass with Cashew leaves, mix some rum and water in this glass, and the person who drinks it will become “as drunk as a fiddler.”

In making rum for my own use, I make colouring from ripe bananas; these are stewed with sugar alone, and well stirred; the process of making it is just the same as described for ordinary colouring; but if the bananas are not thoroughly ripe, this colouring will impart a rough unpleasant taste to the rum. The rum is thrown into a new white oak puncheon, slightly charred inside, and placed on a bench; a large bag containing white oak, or guava wood charcoal, tea, and coffee, is placed above a tub and between it and the puncheon, and the rum is allowed to drop through this, and then into a new puncheon, with a piece of raw beef—of course, a good deal of spirit is lost, but a very pleasant spirit is made. Put one glass of old rum in a quart bottle, fill with water, place a wet cloth round this, and keep it some hours in a cool windy place, it is then ready for use.

But persons who make rum for sale should bear in mind that the loss of a bead, i.e., one degree, is equal to five% of spirit. Distillers calculate that in the mere fact of colouring, and running the rum from the pipe to the puncheon, one bead is lost; that is, 17° proof as run from the still, becomes 18° by the time it is coloured and ready for shipment [This might imply under proof to even more under…]. 100 gallons of 17° would require five gallons of water to reduce it to 18°, and this would take thirty-five gallons of water to reduce it to 25°. In Jamaica 18° [over proof = 67.43% ABV] is the shipping, and 28° [Under proof = 41.44% ABV] the retail proof. Two puncheons of shipping will make three puncheons of retail rum.

I quote an extract from a letter addressed to me by an experienced planter and distiller: “I notice your remarks on the diversity of opinion on setting up flavour and returns from material used. You, as a planter, must know how many extraneous causes affect the value of convertible and non convertiblc sugars, both in the field, the house, and in the manufacturing process. If, therefore, the material is of such varied value in the daily and weekly processes, and these processes are carried out entirely on one plan in each particular still-house, or by each book-keeper, without having a written or educational guide to go by, what can be expected but varied results from every still-house, and from rum made on adjoining properties, with soil, seasons, and the self-same operators to work them.”

“For quality there are exceptional cases which no amount of skill could deteriorate or improve; the flavour is like that of some wines or brandies of choice vineyards: it is as much from the peculiar soil as in the fruit. Of course the working up of the material would affect it more or less, but not primarily, and the heavy or light settings-up, with large or small vats, high or low vessels, would only affect the attenuation in proportion to the superincumbent pressure of liquids in relation to pressure. The heavy set wash of former days was not the cause of the former highly appreciated flavour. It entailed a fearful loss in quantity, but from the large loss of sugar (from want of attenuation) leaving a much larger quantity of saccharate of lime, this causes a much higher caramelization in distilling, and a peculiar formation of an acid (as yet not analyzed) in the dunder, which either with or without the lees (which contain always proportions of the empyreumatic oil) gives the peculiar flavour to each estate’s rum. The real essence (an acrid oil) of rum is in the first process of cultivation and manufacture.”

“A field highly cultivated with nitrogenous substances, giving a luxurious cane as in old time cultivation, will always make a superior quality of rum.”

“As regards the percentage of return, I agree with your remarks. No definite result from still-house books, such as they are, can be arrived at; of one thing, rest cortain, that the waste of materials on every estate I have ever seen could, if funded as a sinking fund to borrow money for permanent improvements, make the investment of money in cane cultivation the best and safest I know of.

“The average result from fair attenuation of 150lbs. of molasses equal to 112lbs. sugar (bearing in mind that the saccharine is not only decomposed by heat, but contains the glutinous or “extractive matter of the cane) is 11.35 of proof rum, or equal to “about 7-3/4 gallons 18° bead, or 35° over proof. You may search Jamaica all over and never find such returns, more particularly if the large proportion of sweets from the boiling-house and rum canes are added.”

The views of this gentleman coincide with mine. The question appears to resolve itself into this: Is it more advantageous to cultivate cane for the production of rum or sugar; if solely for the former, then the ranker the canes are made to grow the more nitrogenous matter they contain, and the better adapted is the juice and the proceeds from the juice (skimmings and molasses) for vinous fermentation, and the greater will be the return in rum. If, on the contrary, ve plant canes to produce sugar, we should cultivate them in such a manner that when brought to maturity they shall contain the least possible quantity of nitrogen, that what little is in the juice should in the process of defecation be extracted from it, for nitrogenous matter is injurious to granulation, and then the question arises: Does it pay better to sell your molasses; reboil it into sugar; or convert it into rum? This is a question, the solution of which must depend in a great measure on the markets to which the produce is sent.

(To be continued.)

In a very elaborate and interesting report made by Mr. J. Wulff, of the Island of St. Croix, he says:—“For the purpose of fermentation the molasses is dissolved in water and mixed with skimmings and sediment from the boiling-house, in such proportions that the wash gauges 10° B. This done, the fermentation sets in spontaneously, and lasts about fourteen days.” No returns are given of quantity of rum produced, but the system and results are similar to those in Puerto Rico; many of the sugar estates in that island being managed by planters from Santa Cruz. Mr. Wulff, in his report, describes the system of sugar-making in both islands; as likewise that of Demerara, and the Usines in Martinique. [Usine being a term for central factory.]

The returns from 100 lbs. of cane-juice he shows to be:—

According to some trials made by me in Ponce, and published in a number of The Sugar Cane in 1873:—100 lbs. juice gave 10.79 lbs. sugar, 4.07 lbs. molasses.

Referring to The Sugar Cane, page 271, “Usine Robert,” I find “21,300 tons of cane gave 1124 tons sugar 1st jet, 300 tons 2nd and 3rd jet, and 109,625 gallons molasses.” Or each 100 lbs. 1st jet sugar produced, as offal crop, 26.69 lbs. of 2nd and 3rd jet sugar, and 60.95 lbs. = 4:45 galls. of molasses.

Page 284, “Usine Riviére Salée,” “1332 tons of first jet gave 848 tons second jet, and 199.616 galls. molasses.” Or each 100 lbs 1st jet dry sugar produced as offal crop 26.12 lbs. of 2nd jet, and 93 lbs. = 6.64 galls. molasses.

This great proportion of molasses on dry sugar is, without doubt, occasioned by too liberal a supply of chemically compounded manures, the use of which has of late years been introduced in Martinique. The planter sells his cane to the Usine by weight. He has signed a contract to do so for a given term of years, but no stipulation was made for density of juice; consequently, his object is to produce a rank heavy cane; such canes contain an excess of nitrogenous matter, as in their knots and rind albuminous and glutinous substances abound which cause, from the process of elaboration, a small return of crystals, and a very heavy offal one in skimmings and molasses.

[Here we see a hint that canes for rum may contain a lot of knots. We also see the word offal repeatedly.]

Turning to figures from Demerara, I find 301,700 galls. canejuice gave 256,743 lbs. dry sugar, and 165,777 lbs. molasses; or each 100 lbs. dry sugar had as its proportion of offal crop 64.56 lbs. = 4.61 galls. of molasses.

On the north coast of Puerto Rico, 100 lbs. of dry sugar produced 60 lbs. equal to 4.28 galls. of molasses.

On some trials made in Ponce, 100 lbs. of dry sugar had produced an offal crop 58.82 lbs. = 4.20 galls. of molasses.

Copying Mr. Robert Graham, C.E., who in “La Eronica de Ponce,” in his description of the Luisa Factory, says: “737,179 lbs. cane gave 61,180 lbs. sugar 1st jet; the molasses from this gave 12,240 lbs. as 2nd jet sugar, and 275 gallons molasses.” This, with the washings of apparatus, which, no doubt, was considerable, gave 275 galls. of rum.

Thus each 100 lbs. of dry sugar 1st jet produced as offal crop 20.61 lbs. of 2nd jet, and 6.75 lbs. molasses = 48 galls. Knowing this locality to be one of the most favoured spots for the production of rich, healthy canes, giving a juice as free from impurities as it is possible to find in cane juice, yet I wrote to enquire. Mr. Graham, in reply, states:—”My report on Boyne’s Factory is the simple fact.”

The yield was—

On a trial made last February, on the Ysabel Estate, Ponce, the property of Mr. William Oppenheimer, the canc juice was reduced to syrup, in the “Balseyro” battery, and concentrated to grain in wetzel pans: this method is described in No. 60 of The Sugar Cane.

An acre of canes produced 60 cart loads, equal to 81,600lbs. of cane, 1360lbs. to each load, drawn by one yoke of oxen (*). The juice from those weighed 48,825lbs., extraction, 59.83. This juice 11½°B, gave dry sugar, 6833lbs.; molasses, 2274lbs.; or sugar, 8.373; molasses, 3.127; or 11.5% on weight of cane; or for each 100lbs. of dry sugar, an offal crop of 37.37lbs. of molasses.

(*) N.B.—In Puerto Rico they never use bows, the cattle are yoked by the horn.

On an estate I visited in Jamaica, 506,400 gallons cane juice produced 684,690lbs. centrifugaled sugar, and the average yield was 61.25lbs. sugar; 38.75lbs. molasses, % on 35 distinct trials.

At the same ratio the offal crop would have been 433,123lbs., equal to 30,324 gallons of molasses; this, with the skimmings made 482,000 gallons wash, giving 21,940 gallons, 18° rum, equal to 29,619 gallons of 25°, or proof rum.

The offal crop of each 100lbs. of dry sugar shipped, equaled 63.25lbs., equal to 4.51 gallons of molasses.

100 gallons of juice gave 135lbs. of sugar, 85lbs of molasses, or 3.35 gallons of 18° rum. (†)

(†) Some of these figures will be altered by the correction furnished by Mr. Mitchell (see p. 547), and the proportion of rum per 100 galls. of cane juice will be raised to 375 gals.—Ed.

100 gallons of molasses, or its equivalent in skimmings, gave 60.55 gallons of 18°, equal to 81.74 gallons of 25° rum, or 1.22 gallons of molasses to 1 gallon of proof rum.

On another estate, 589,200 gallons of juice had made 323 large hogsheads 42 in truss, yielding 28,630 gallons of molasses, which, with the proportion of skimmings, produced 461,000 gallons wash, giving 20,400 gallons 18°, equal to 27,540 gallons of 25°, or proof rum.

One gallon molasses to .77 rum or 1.29 galls. molasses to one gallon proof rum.

On a third estate 164,800 wash made 8,631 galls. 18° rum = 11,651 galls. of 25° or one gallon of molasses to .78 rum, or 1.28 galls. molasses to one gallon rum.

I must, however, observe on these three examples 7% of cane juice ground was calculated by me as being passed into the liquor loft in the shape of skimmings,—this quantity is not in excess; but planters generally calculate their return of rum per gallon of molasses used, throwing in the skimmings and sweet water from the washings of the apparatus as nothing. If on the three estates mentioned in Jamaica, molasses alone is calculated, the yield would then be the following:—

Not having with me my general note-book I cannot state accurately the number of gallons of wash distilled, but with 2,450 galls. of skimmings, the proceeds of 57,500 galls, of cane juice elaborated into sugar, or 4.26% of skimmings on cane juice ground, and with 2,400 gallons molasses, the drainings or offal crop from 56,000 lbs. of dry sugar shipped some years past in Puerto Rico, I made 2,450 galls. of 25° proof rum, or one gall. 26° to 1.14 gall. molasses, or one gall. molasses to .87 of proof rum.

Naturally, it might be asked why fix 7% as the quantity of skimmings when on this trial 57,500 galls. of juice only gave 4.26%. Here I carefully superintended the cleaning or skimming of each copper, 600 galls. cane juice. A very active man attended to the grand copper, and we measured with care the skimmings so as to convince ourselves what might be the smallest quantity we had to take off to clean the liquor; such a mode of working could not be carried out constantly in a boiling-house. I have frequently seen 10% and upwards taken as skimmings from the cane juice.

The usines in the French islands produce 10 to 11% of proof spirits on wash distilled, and an average yield of 70% on molasses used. Usine Robert gave the unusual return of 83.63% on molasses; but in these usines no account is taken of other sweets used; it is the same on sugar estates generally, therefore, it is almost impossible to arrive at a just estimate of the sweets used in any given distillery. We frequently hear planters say they made this or that return for molasses used, but the other sweets, as skimmings and washings are not mentioned. As an illustration, take my return 2,400 galls. of molasses, which made 2,450 galls. of proof rum, and you have 102 galls. rum 25° for each 100 galls. molasses, whereas, the fact was the skimmings equaled 408 galls. molasses, so that in point of fact only 87 galls. of proof spirit were obtained from each 100 galls. molasses, or its equivalent used; moreover, as in all boiling-houses the water used to cool down on grinding-off day would have equaled some few gallons more.

In a statement I received of the yield of spirits in Demerara—“They seldom obtain less than 8% and frequently 9% on wash distilled; they get one gallon of rum for 12 gallons wash set up at 8° B [1.058]. . . Estate and some others well managed get one gallon from less than 11 gallons of wash. At . . . Estate 79,200 galls. wash gave 7,350 gallons rum 42° O.P., or 9.28 on wash distilled. This estate takes 1.75 gallons of molasses to one gallon of rum; some estates take two gallons, but never more.”

[It is interesting to see the author name names when he wants to but then omit them . . . when he doesn’t.]

Deresné’s still at Boyné’s, Puerto Rico, is said to take 1.50 galls. molasses to one gallon of rum.